THE CHALLENGE

When the equipment was mobilised and began removing the concrete, tunnel 1 demolition operations went quickly and according to plan.

When the subcontractor began operating the Conjet 557 in Tunnel 2, it was discovered that not only was the concrete extremely deteriorated, the thickness was also very inconsistent, ranging anywhere from 8 to 24 inches (20-61 cm) depending on the location. As a result, the original plan to cut 12 inches (30 cm) deep and place new concrete to form structural ribs had to be abandoned.

Rather than installing ribs, the engineering team decided to pivot to a new structural strengthening approach that involved cutting thicker, 6 in deep x 10 ft long (15 cm x 30 m) panel sections. Each panel section would have a reinforcing mat of high-strength #6 rebar. To maintain structural integrity during this process, each panel section would need to be cut to the proper depth, replaced with rebar and concrete, and cured before work could begin on the next section.

THE RESULTS

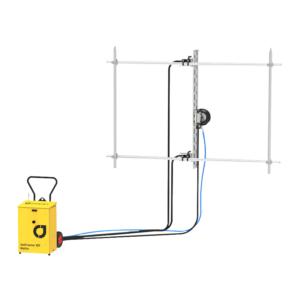

Using the ConjetONE control system, the subcontractor was able to easily adjust the parameters of the Conjet 557 MPA to cut at different speeds across the cutting head, ensuring a 6 inch (15 cm) deep removal, even across the curved crown of the Tunnel. The contractor team then came back in and installed new rebar and mesh, filling in the new reinforcement system with Shotcrete.

The revised construction plan was executed successfully, and the concrete repairs were completed. The Project Superintendent stated, “In view of the unexpected challenges, we are extremely pleased with the outcome of the Cornell Tunnel restoration project. The subcontractor exceeded our expectations with respect to the concrete removal work. The hydrodemolition process provides an incredibly efficient, high-quality removal that is perfect for applying a new concrete overlay which will extend the useful lives of these tunnels for many years to come. Hydrodemolition was the only way to go for this work. It was far superior to any other methods we could have used for the concrete removal.”

The Cornell Tunnel restoration project is a great example of how skilled contractors and engineers can deploy cutting-edge hydrodemolition equipment to preserve vital concrete infrastructure, regardless of the unexpected challenges that may arise in the process.

My Account

My Account