Water working for you.

An Ultra-High Pressure (UHP) water blasting system can be used for your hardest commercial and industrial stripping/cleaning jobs. With UHP water systems, there is low impact on the environment and it is a cost effective way to prepare a blasting surface.

Best uses for UHP systems would be for removing rust, resins, chemical residues, scale and tick or abrasion resistant coatings. The abrasion resistant coatings could include coal-tar epoxies, chlorinated rubber, glass-flake coatings and polyurethanes. These systems work by cutting directly through the coating or rust, which dis-bonds it from the exterior and then washes it off. This results in a completely clean surface.

KEY COMPONENTS IN UHP WATER SYSTEMS

UHP water jetting systems have a high pressure pump that is extremely important. The pumps deliver pressures between 6,000psi and 40,000 psi and have power ratings up to 1,000 horsepower. These systems can be powered by electric or diesel, and skid, trailer or container mounted.

For hazardous environments, special models are obtainable. The Protective Apparel for the workers operating the UHP equipment. This apparel is designed specifically for UHP Water Jet Operators to protect them from a high pressure water stream.

The UHP pump connects to a hose that connects to the cleaning tools. There are many tools that are available for lots of different applications, including:

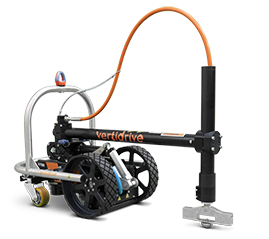

- Vacuum-attached crawlers

- Internal tank cleaning head

- Internal pipe and tube cleaning tools

- Floor and grate cleaners

- Remote-controlled robotic cleaning systems

USING ULTRA HIGH PRESSURE (UHP) FOR SURFACE PREPARATION

Using UHP water for surface preparation is becoming more popular. Not only is UHP jetting dustless, it also decreases the amount of waste from the project due to the fact that there is no abrasive media being used. Other tasks can be completed around the blasting site with UHP as well since no abrasive has to be used.

A great thing about UHP is that the clean surface does not get blasted with any contaminants. It actually makes it even cleaner after taking off contaminants and soluble salts. UHP stripping will wash the surface and transform it back to its’ original profile. Note that is does not create a new surface profile.

Water jetting systems are also commonly used among other tools to take paint and coatings off, get abrasive blast wet, slice slag out of drain lines, take coatings from floors and grates, demolish concrete, wash interiors of tanks, and cut steel plates.

BLASTING WITH HP & UHP

The Society for Protective Coatings (SSPC) and NACE International have created four surface preparation standards for water jetting. The highest standard is SSPC-SP WJ-1/NACE WJ-1. SP WJ-1 requires cleaning metals to bare substrate using HP.

The other three standards in this set are:

- SSPC-SP WJ-2/NACE WJ-2

- SSPC-SP WJ-4/NACE WJ-4

- SSPC-SP WJ-3/NACE WJ-3

NACE/SSPC produced a guide that shows uncoated and coated rusted steel surfaces cleaned to WJ-4, WJ-3. WJ-2 and WJ-1 finishes. The other photos show degrees of heavy, moderate and light flash rusting after the UHP process.

PERSONAL PROTECTIVE EQUIPMENT APPROPRIATE TO WATER JETTING

Before starting UHP work, a risk assessment and identification has to be done in order to choose PPE. The correct PPE has to be worn in hazardous areas.

My Account

My Account