BlastOne has been working as a distributor of GMA Garnet for over 40 years!

Over the last 20 years GMA Garnet has become the primary abrasive used for sandblasting in Australia and New Zealand. BlastOne has helped contractors on different projects across Australia and the globe, and we understand the requirements that different projects bring. We trust this article helps you to understand what grade of Australian garnet we recommend for your application.

While there is no such thing as a does-all sandblasting abrasive, GMA Garnet comes closest. It has been the abrasive of choice for blasting multiple materials – steel, aluminium, stainless steel, glass. It has performed tasks as varied as frosting glass, cleaning up stainless steel after TIG welding, and removing corrosion on marine vessels.

Locations:

New Zealand: Auckland & Christchurch | Contact Us for Our Full Availability Across New Zealand!

The Power of GMA Garnet as a Blasting Abrasive

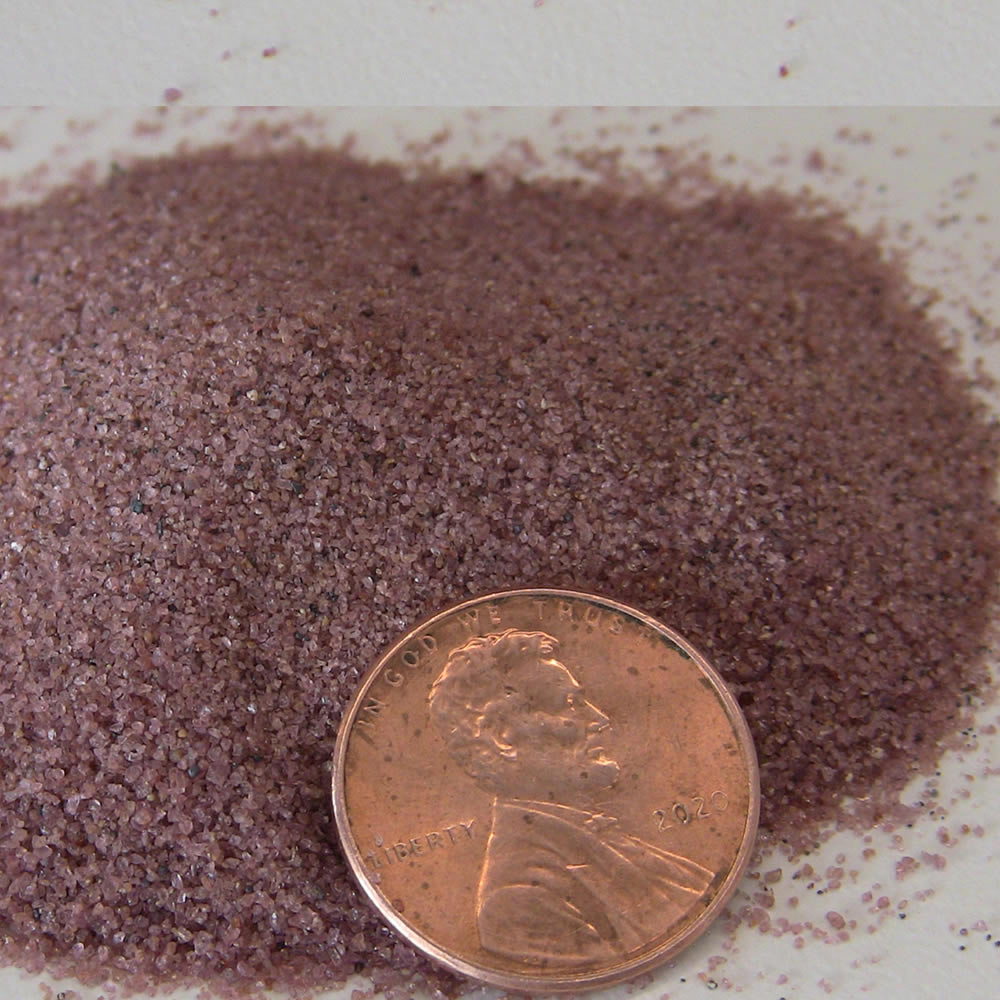

Also known as the Almadine garnet, is a versatile and durable type of garnet that is gaining popularity in the blasting industry. This garnet is known for its bright pink colour, high hardness, and ability to effectively remove surface contaminants.

Characteristics of GMA Garnet for Blasting

An ideal choice for blasting abrasives due to its unique characteristics. Some of the key advantages of using it for blasting include:

- Hardness: GMA Garnet™ is harder than most other abrasives, producing a deeper, more consistent profile when blasted at the same pressure.

- Durability: GMA Garnet™ is tougher than most other abrasives, reducing the tendency to fracture on impact, resulting in deeper profiles and higher efficiency blasting.

- Low Dust Generation: GMA Garnet™ is sub-angular in shape, with enough edges to create deep profiles while minimising embedment.

- Low Profile: GMA’s heavier, denser abrasive grains outperform less dense abrasives, delivering more energy to the surface and creating deeper, consistent anchor profiles when blasted at the same pressure.

Sand Blasting Warning: Crystalline silica is a known Group 1 Carcinogen. Using Silica Sand as an abrasive blasting media has been identified by Worksafe Australia as causing Silicosis (lung condition), leading to severe illness and death. For more information please refer Silica Sand Warning

Knowledge & Learning

Videos from the Experts

How to | Primed Insights | Safety Tips

3 Tips for recycling abrasive on jobsites

Abrasive Contaminants Left on Blasted Surface

How Using The Correct Abrasive Grade Improves Nearly Everything

GMA More than just Australian Garnet

Low Dust Blasting with GMA Australian Garnet

GX-GMA GARNET vs. SLAG ABRASIVE

Understanding Abrasive Sizing for Sand Blasting

ANGULARITY: A Growing Sandblasting Spec

Abrasive Particle Size Testing

Customer Testimonials

The Original Australian Abrasive Garnet Supplier!

The Pioneering Global Abrasive Garnet Supplier

GMA Garnet is an excellent choice for blasting abrasives due to its hardness, durability, low dust generation, and angular shape. With its ability to improve surface quality, increase productivity, and reduce environmental impact, the Australian GMA Garnet is a versatile and powerful tool for any blasting application. If you are looking for a reliable and effective blasting abrasive, consider this incredible media.

BlastOne New Zealand, supplies quality Australian GMA Garnet, Surface Preparation and Corrosion Control equipment, in many different industries including Oil & Gas, Mining, Structural Steel Fabrication,

Water Infrastructure, Marine and Bridge Refurbishment work.

Auckland & Christchurch: 0800 190 190

My Account

My Account