Blast Pots and Machines

SANDBLASTING MACHINES, EQUIPMENT, WET BLAST SYSTEMS, POTS & ABRASIVE GRIT BLASTING EQUIPMENT

BlastOne has a complete range of sandblasting machines and equipment to suit all your projects & applications. Read our Article, Blast Machine Equipment Buying Guide , to help choose the bset machine for you. We offer a range of machines from Large to Small Bulk Pots, Mega Blasters, Wet, Slurry, Vapor, Wet, Soda, Standard Blast Pots, Hoppers, Sandblasting Systems & Equipment, Industrial, Ecoquip, Amphi-blasters, Ibix 25 & Ibix 40 Portable & Commercial Grit Equipment. Specialist sandblasting machines and equipment for blasting the internal & externals of pipes, Bulk Tanks for shipyards, and packaged abrasive blasting & air-driers for use on offshore oil & gas platforms, BlastOne has the complete solution, as a leading abrasive sandblasting equipment & grit abrasive supplier. BlastOne has what you need at a convenient location near you. When you need something from large or small, BlastOne is your partner.

Showing 1–15 of 27 results

-

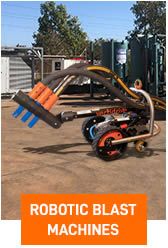

RUBVDV700BlastOne's VertiDrive V700 Blasting Robot represents the cutting edge in surface preparation technology, engineered to revolutionize large-scale blasting projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for performance, efficiency, and safety.

RENT OR PURCHASE THIS VERSATILE, MULTI-PURPOSE SOLUTION!

- Blasting Robot

- Compatible for use on horizontal, overhead, and vertical surfaces

- Can operate upside down on steel surfaces via magnets

- Interchangeable applications (washing / hydroblasting / abrasive blasting)

- Wirelessly controlled - keeps workers out of harm's way

- Strategically designed for compact working radius

- Reconditioned older VertiDrive models may be available for sale

Different packages available

RUBVDV700BlastOne's VertiDrive V700 Blasting Robot represents the cutting edge in surface preparation technology, engineered to revolutionize large-scale blasting projects. This next-generation robotic system, exclusively developed by BlastOne, sets a new industry standard for performance, efficiency, and safety.RENT OR PURCHASE THIS VERSATILE, MULTI-PURPOSE SOLUTION!

- Blasting Robot

- Compatible for use on horizontal, overhead, and vertical surfaces

- Can operate upside down on steel surfaces via magnets

- Interchangeable applications (washing / hydroblasting / abrasive blasting)

- Wirelessly controlled - keeps workers out of harm's way

- Strategically designed for compact working radius

- Reconditioned older VertiDrive models may be available for sale

Different packages available

-

BMS10The “Mitey-Mite 1.0 cuft Blast Machine” (SKU: BMS10) offers efficient and reliable spot blasting, packed in a compact size. With a 70 kg Garnet capacity and micro valve metering, it's perfect for touch-ups.

- Smallest production style pot available

- The 1.0 cuft capacity will hold 70 kg of Garnet

- Ideal for in-plant or onsite touch up work

- Comes with Micro Valve Metering Valve

- Comes with moisture trap

- 1" Piping

BMS10The “Mitey-Mite 1.0 cuft Blast Machine” (SKU: BMS10) offers efficient and reliable spot blasting, packed in a compact size. With a 70 kg Garnet capacity and micro valve metering, it's perfect for touch-ups.- Smallest production style pot available

- The 1.0 cuft capacity will hold 70 kg of Garnet

- Ideal for in-plant or onsite touch up work

- Comes with Micro Valve Metering Valve

- Comes with moisture trap

- 1" Piping

-

BMS20

- 2.0 cuft capacity will hold 140 kg of Garnet

- Ideal for small shops or occasional blasting

- Comes with Micro Valve Metering Valve

- Comes with moisture trap

- 1" Piping

BMS20- 2.0 cuft capacity will hold 140 kg of Garnet

- Ideal for small shops or occasional blasting

- Comes with Micro Valve Metering Valve

- Comes with moisture trap

- 1" Piping

-

- Manufactured by Schmidt Abrasive Blasting & Axxiom Manufacturing to BlastOne specifications

- Valving system designed to have a maximum of 3psi pressure drop

- Specified Capacity (approx)

- 3.5 cu ft / 99 litres

- Abrasive Capacity (approx)

- Garnet - 230 kg

- Steel Grit - 390 kg

- Pressure Rating: 150psi

- Includes: Moisture separator and inlet fitting

-

*Most Popular Blast Pot*

- Manufactured by Schmidt to BlastOne specifications

- Valving system designed to have a maximum of 3psi pressure drop

- Specified Capacity (approx)

- 6.5 cu ft / 185 litres

- Abrasive Capacity (approx)

- Garnet - 430 kg

- Steel Grit - 700 kg

- Pressure Rating: 150psi

- Includes: Moisture separator and inlet fitting

-

- Wet blast or dry blast with a single unit

- Minimal water usage (less than 1 pint /½ litre per minute) with proprietary Schmidt M.I.S.T. technology that allows precise control of the amount of water injected into the air stream while blasting

- Set and forget switching between machine modes

- Abrasive tank is dry so there is no need to drain water to refill with abrasive. This creates a significantly cleaner job site and is more efficient

- Industry-leading productivity and reliability from Schmidt abrasive blasting technology

- Schmidt Tera Valve XL abrasive metering valve offers precise and repeatable control of a wide range of coarse or fine abrasives

- Wide range of blasting pressure capabilities from 10 to 150 psi

- Toggle between wet blast, dry blast, and blow-off using a single control panel

- Increased portability

-

BMS1001TV

- 10.0 cu ft Blast pot

- Manufactured by Schmidt to BlastOne unique specifications

- Single outlet Thompson Valve II abrasive metering valve

- Approx 670 kg garnet abrasive capacity

- Comes with pnuematic deadman handle and 20m of control hose

- Excellent for a blastroom application with 1-2 blasters

- Meets all Australian Standards

BMS1001TV- 10.0 cu ft Blast pot

- Manufactured by Schmidt to BlastOne unique specifications

- Single outlet Thompson Valve II abrasive metering valve

- Approx 670 kg garnet abrasive capacity

- Comes with pnuematic deadman handle and 20m of control hose

- Excellent for a blastroom application with 1-2 blasters

- Meets all Australian Standards

-

BMS200

- 20.0 cu ft Blast pot

- Manufactured by Schmidt to BlastOne unique specifications

- Dual outlet Thompson Valve II abrasive metering valves

- Approx 1350 kg garnet abrasive capacity

- Comes with two pneumatic deadman handles and two lengths of control hose

- Excellent for a blastroom application with 1-2 blasters

- Meets all Australian Standards

BMS200- 20.0 cu ft Blast pot

- Manufactured by Schmidt to BlastOne unique specifications

- Dual outlet Thompson Valve II abrasive metering valves

- Approx 1350 kg garnet abrasive capacity

- Comes with two pneumatic deadman handles and two lengths of control hose

- Excellent for a blastroom application with 1-2 blasters

- Meets all Australian Standards

-

The Schmidt® M-Series Multi-Media Blasters are built for pros who need one blast pot that handles it all. From light cleaning with soda to aggressive steel grit work, this series delivers full control, rugged performance, and reliable media flow—job after job.

- Blasts a wide range of abrasives: soda, grit, plastic, glass, and more

- Available with choice of the tried-and-true Thompson II or the latest TeraValve XL, for the ultimate in precision abrasive metering. Both come with a slotted tungsten carbide sleeve.

- G3 Trigger Deadman now standard across all models with the compact BAABS also included in all except the Mini M-Series.

- Pressure and tank regulators dial in your blast profile for each job. Blasting pressure can be set from 10 to 150 PSI.

- Media vibrator boosts flow performance for lighter abrasives

- Quick-detach valve and media shutoff for simplified service

- Available sizes: Mini M-Series (0.9 cu ft), M-11 (1.5 cu ft), M-21 (2.0 cu ft), M-31 (3.0 cu ft)

-

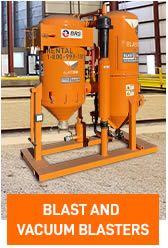

VCBRSMP

- Abrasive holding capacity of 0.3 cu ft / 8.5 liters

- Blasting rate up to 2.0 m2 per hour

- Compressed Air Requirement 185 cfm

- On wheels for easy access. Includes fork pockets

- Recirculating compact blast & recovery unit

- 100% compressed air driven - no electricity required

VCBRSMP- Abrasive holding capacity of 0.3 cu ft / 8.5 liters

- Blasting rate up to 2.0 m2 per hour

- Compressed Air Requirement 185 cfm

- On wheels for easy access. Includes fork pockets

- Recirculating compact blast & recovery unit

- 100% compressed air driven - no electricity required

-

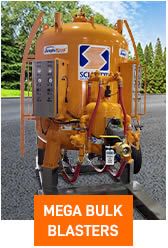

BMS752TVBULK BLAST POT

- Blast Bulk Pot capacity 75 cu ft / 2100 liters

- Manufactured by Schmidt to BlastOne unique specifications

- Garnet abrasive capacity - 5 tonne Bulk Blaster

- Ideal for mounting to the back of a truck

- Comes with 2 Thompson Valve abrasive metering valves, can have upto 4

- Skid Mounted Mega Pot

BMS752TVBULK BLAST POT- Blast Bulk Pot capacity 75 cu ft / 2100 liters

- Manufactured by Schmidt to BlastOne unique specifications

- Garnet abrasive capacity - 5 tonne Bulk Blaster

- Ideal for mounting to the back of a truck

- Comes with 2 Thompson Valve abrasive metering valves, can have upto 4

- Skid Mounted Mega Pot

-

- Wet blast or dry blast with a single unit

- Lightweight and most portable in the AmphiBlast family

- Minimal water usage (less than 1 pint / ½ litre per minute)

- Set and forget switching between machine modes

- Abrasive tank is “dry” so there is no need to drain water to refill with abrasive. This creates a significantly cleaner job site and is more efficient

- Schmidt Tera Valve™ XL abrasive metering valve offers precise and repeatable control of a wide range of coarse or fine abrasives

- Electric water pump provides high flow water during softwash or wash down

- Wide range of blasting pressure capabilities from 10 to 150 psi

- Toggle between wet blast, dry blast, and blow-off using a single control panel

- Can fit through a 24" doorway with ease (even with the onboard tank)

-

BMS1602TVH1600BULKBLASTER / MEGABLASTER

- Specified capacity 160 cu ft / 4500 liters

- Manufactured by Schmidt to BlastOne unique specifications

- Garnet abrasive capacity - 23800 lbs / 10.8 tonne

- 1600 cfm Airprep mounted directly on the front of the MegaBlaster

- Comes with 2 Thompson Valve metering valves, up to 4 outlets possible

- Skid or Trailer Mounted

- Hybrid Bulk Blaster with built-in Air Drier

BMS1602TVH1600BULKBLASTER / MEGABLASTER- Specified capacity 160 cu ft / 4500 liters

- Manufactured by Schmidt to BlastOne unique specifications

- Garnet abrasive capacity - 23800 lbs / 10.8 tonne

- 1600 cfm Airprep mounted directly on the front of the MegaBlaster

- Comes with 2 Thompson Valve metering valves, up to 4 outlets possible

- Skid or Trailer Mounted

- Hybrid Bulk Blaster with built-in Air Drier

-

BMPIPSYSL375ACT

- Dual Wheeled Trailer Mounted Blasting Package

- BMS6.5 blast machine with Thompson Valve outlet

- 400 cfm AirPrep Air Drier

- 375 cfm 150 psi diesel air compressor

- Breathing air filter

- Carbon monoxide alarm

- Tool box

- Hose rack

- Room for 1 skid of abrasive

- Dustless Vapor Blasting

BMPIPSYSL375ACT- Dual Wheeled Trailer Mounted Blasting Package

- BMS6.5 blast machine with Thompson Valve outlet

- 400 cfm AirPrep Air Drier

- 375 cfm 150 psi diesel air compressor

- Breathing air filter

- Carbon monoxide alarm

- Tool box

- Hose rack

- Room for 1 skid of abrasive

- Dustless Vapor Blasting

-

FOR RENTAL OR PURCHASE

- Combination Skid - MistBlaster and AirDryer Package

- Capable of doing wet and dry blasting - ultimate flexibility for any job!

- 6.5 cu. ft. Schmidt Blast Pot with MistBlaster Conversion

- Teravalve XL Abrasive Metering Valve

- 400cfm Moisture Removal System (Select Deliquescent Air Dryer or Squat AfterCooler)

- 189 liter water tank & pump

- Select if you do or don't want the Operator Accessories Kit (RPB Breathing air filter and GX4 CO Monitor, 5cm Bull hose, 3.175cm SupaFlex Blast Hose, Nova 3 Blast Helmet, and #6 Blast Nozzle)

Industry Leading Sandblasting Machines, Blast Equipment & Sand Blast Pots. Australia’s leading abrasive blasting system manufacturer.

Are you needing high performance, superior sandblasting equipment? BlastOne offers a wide variety of blast units ranging from small blast pots to larger bulk blasters and even up to 800 cuft megablasters. Whatever the job, we have the blasting equipment to get it done. Our hand-held Tornado Blaster is a highly effective tool for those needing greater production per blaster, and should interior pipes be an issue for your project, our robotic internal pipe tools come in sizes to fit nearly any diameter pipe.

We are a proud seller of Schmidt blast equipment sandblaster supplies and tools, and each sandblast pot comes with a standard warranty.

Sand Blast Pots

Sizes of sandblast pots available from 1.0 cu.ft to 800 cu.ft – suitable for mineral or steel abrasives.

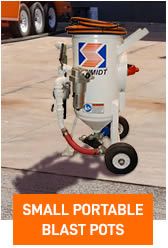

Portable Sand Blasting Machines

BlastOne is Australia’s leading manufacturer & provider of sand blasting machine. If you are looking for sand blasting machine supplies in Australia, BlastOne is a great partner.

Blast Cleaning Equipment

Abrasive Blast Cleaning Equipment is ideal for remove of paint, rust & scale from steel to provide a clean sand blasted surface profile, to provide a class of blast suitable for new protective coatings. Blast Clean with abrasive creates an anchor pattern to provide excellent coating adhesion & key for coatings to adhere to.

Portable Sand Blaster

A portable sand blast equipment or abrasive blasting unit, is used when moving from job site to jobsite, and the large wheels & maneuverability allows for portability when grit blasting on site, or within a contained blast area. Small portable sandblasting units & equipment can be elevated or taken in lifts up to areas where abrasive blasting & spray painting is occurring.

My Account

My Account