Why use Airless Spray Painting Equipment Replacement Parts?

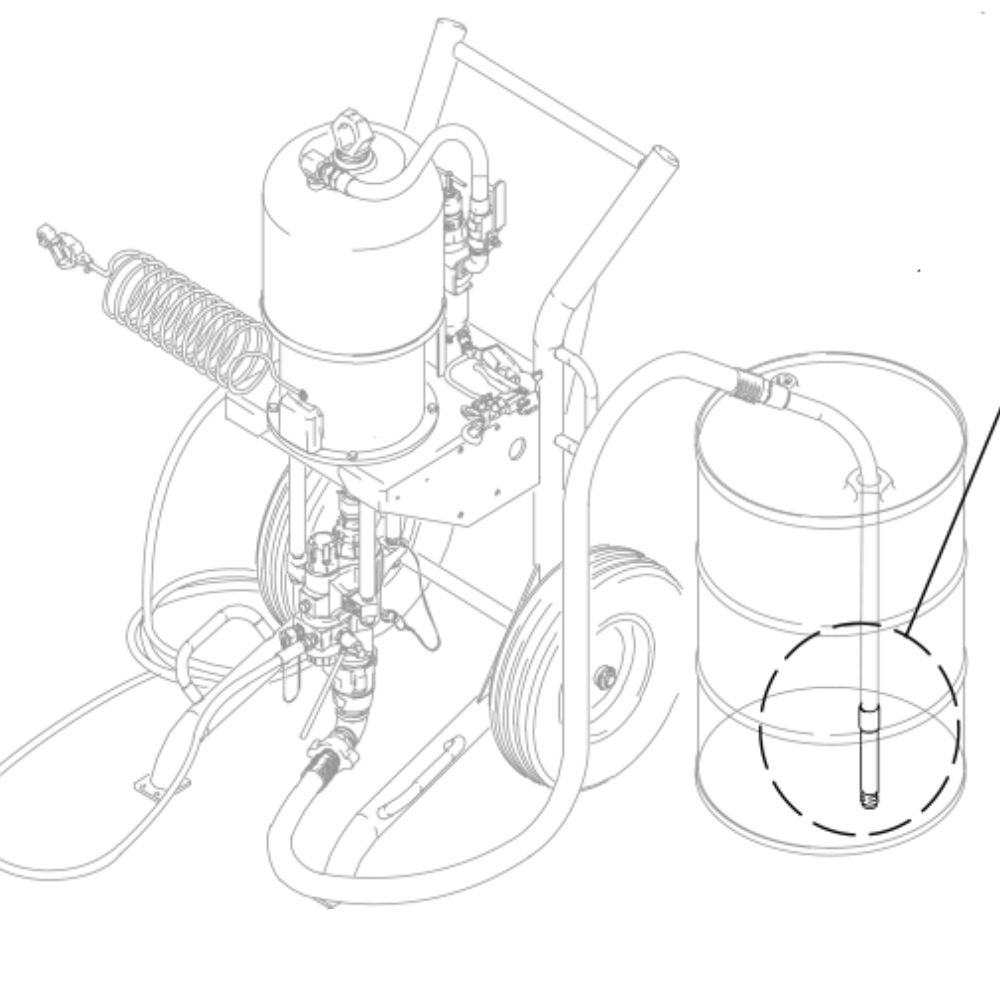

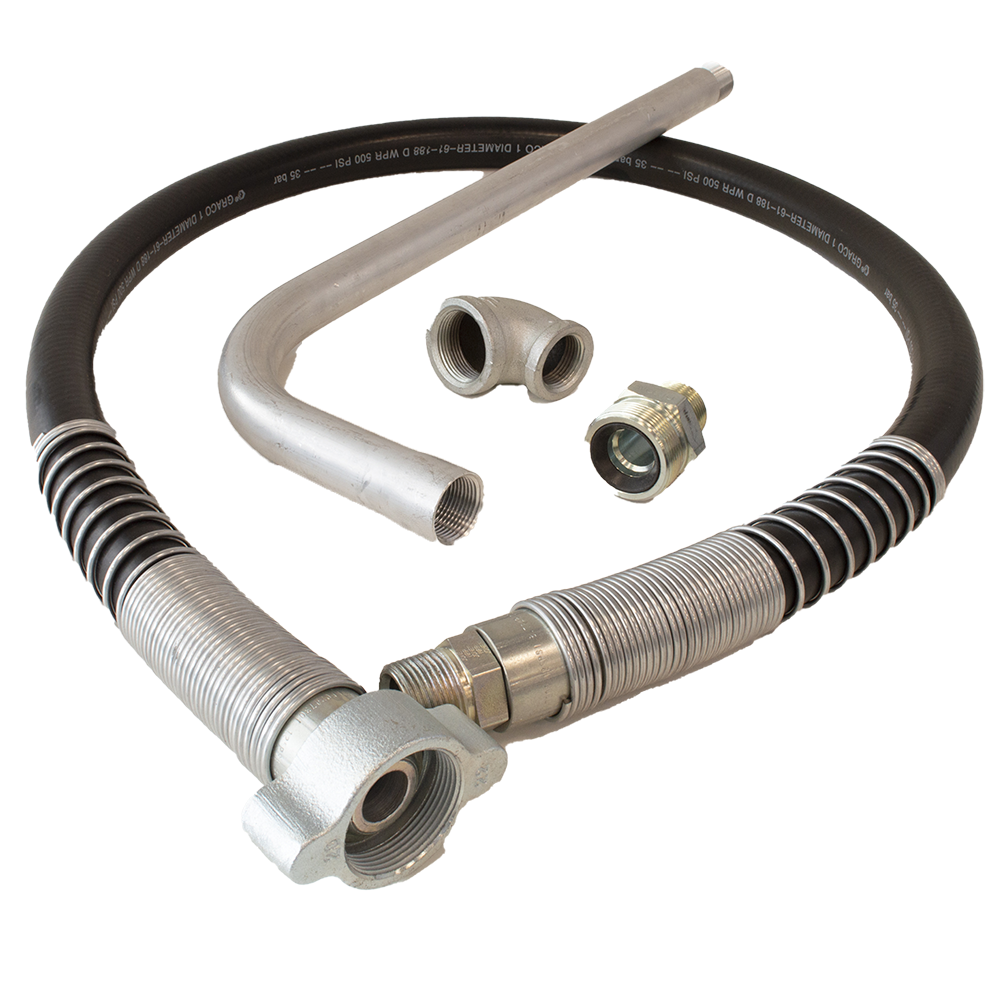

Spray painting equipment is subject to very harsh treatment – attack by solvent and abrasive materials, an unforgiving environment, rough handling, amongst other things. Consequently, the replacement of spare parts is constant. In addition, many pieces of airless spray painting equipment are designed to be adaptable to suit differing tasks. For example, airless spray guns can be fitted with different spray tips and filters to suit different coatings. As a result, a constantly replenished stock of replacement parts in the field is essential.

Common issues with Airless Spray Painting Equipment Replacement Parts

The main issue with airless spray painting parts is recognizing when they are worn. Continued use with worn components risks quality failures, total equipment failure and injury. Some indications of wear in conventional spray equipment include…

- Spray pattern becoming shorter and wider. – Worn spray tip

- Airless sprayer will not prime. – Worn packings, piston rod, and/or cylinder

- Fluid leaking from the top of the piston – Packings and/or piston rod worn

Important considerations when choosing the right Airless Spray Painting Equipment Replacement Parts

One of the most important considerations when selecting airless spray painting replacement parts is whether they are genuine OEM parts. Due to the volume of replacement parts consumed by the Protective Coatings Industry a large “knock-off” parts industry has sprung up. In the main, these “knock-off” are noticeably inferior. Problems caused by these parts include short life, compromised results quality, engineering standards failure, increased risk of injury, etc. Purchase and use of these of these parts is false economy in that they are not really saving you money.

My Account

My Account